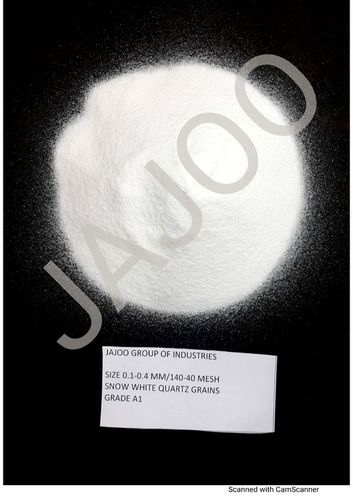

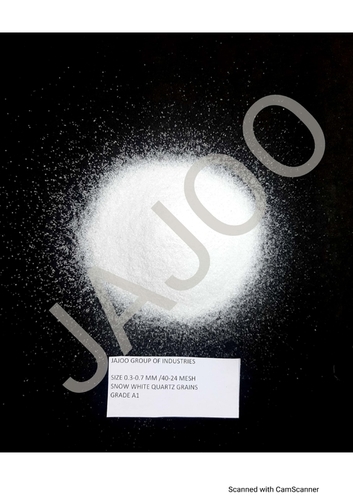

Quartz Grains

Quartz Grains Specification

- Water Absorption

- 1%

- Density

- ~2.6 2.7 Gram per cubic centimeter(g/cm3)

- Surface Finish

- Smooth

- Purity(%)

- 98%

- Melting Point

- ~1710C

- Application

- Steel, glass, foundry, and ceramic industries

- Product Type

- Mineral Refractories

- Types of Refractories

- Basic Refractory

- Shape

- Powder

- Strength

- High compressive and mechanical strength

- Color

- White

Quartz Grains Trade Information

- Minimum Order Quantity

- 27 Tons

- FOB Port

- JAIPUR

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Letter of Credit at Sight (Sight L/C), Cash in Advance (CID), Cheque

- Supply Ability

- 10000 Tons Per Day

- Delivery Time

- 3-4 Days

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Exports Packaging

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO, Moody Rated

About Quartz Grains

Premium Quality for Industrial Applications

Our highly pure (98%) white quartz grains are meticulously processed to deliver outstanding compressive and mechanical strength. Their smooth finish and precise shape in powder form ensure uniformity in manufacturing processes and efficiency in applications across the steel, glass, ceramics, and foundry industries.

Versatile and Reliable Material

Engineered to meet demanding standards, these basic refractory quartz grains offer low water absorption and a high melting point, supporting resilience and stability in high-temperature environments. As a key supplier in India, we cater to varied industrial needs by maintaining strict quality control at every stage.

FAQs of Quartz Grains:

Q: How are white quartz grains used in the steel and foundry industries?

A: White quartz grains serve as a refractory raw material in the steel and foundry sectors. Their high compressive and mechanical strength, along with low water absorption and a melting point of around 1710C, make them ideal for withstanding the intense heat and mechanical stresses encountered during metal casting and steel production processes.Q: What benefits do quartz grains with 98% purity offer to glass and ceramic manufacturers?

A: Quartz grains with 98% purity ensure minimal contamination, resulting in clearer, higher-quality glass and durable ceramics. Their smooth surface and consistent granularity support precise ingredient blending and uniform melting, which are essential for optimal finished product quality.Q: When should basic refractory quartz grains be chosen over other types for industrial applications?

A: Basic refractory quartz grains are best selected when high resistance to heat and mechanical pressure is necessary, and when minimal reactivity with slags or melts is required, as in the production of steel, glass, and ceramics. Their reliable performance at temperatures up to 1710C makes them a preferred choice for these demanding settings.Q: Where do you distribute and export your quartz grains from?

A: We operate as a manufacturer, exporter, distributor, supplier, and trader based in India. Our distribution network ensures timely delivery of quartz grains to both domestic clients and international partners in regions requiring quality refractory materials.Q: What is the refining process for achieving high purity in quartz grains?

A: The refining process involves careful selection of raw quartz, followed by rigorous washing, crushing, and grinding to produce a uniform powder. Advanced techniques are used to eliminate impurities and attain a 98% purity, resulting in superior performance for industrial uses.Q: How does the low water absorption of quartz grains benefit foundry operations?

A: With water absorption at just 1%, the quartz grains reduce the risk of steam-related defects and spalling during the casting process. This enhances mold stability, improves finished product integrity, and minimizes waste in foundry operations.

Price 2000 INR/ Ton

- Minimum Order Quantity

- 27 Tons

- Supply Ability

- 10000 Tons Per Day

- Delivery Time

- 3-4 Days

- Main Domestic Market

- All India

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Quartz Powder Category

Snow White Quartz Grains

Price 2000 INR / Ton

Minimum Order Quantity : 27 Tons

Specific Gravity : 2.65 g/cm

Strength : High compressive and mechanical strength

Density : 2.65 Gram per cubic centimeter(g/cm3)

Water Absorption : 1%

Quartz Powder

Price 1000 INR / Ton

Minimum Order Quantity : 27 Tons

Specific Gravity : 2.6 2.7 g/cm

Strength : High compressive and mechanical strength

Density : ~2.6 2.7 Gram per cubic centimeter(g/cm3)

Water Absorption : 1%

Quartz Silica Powder

Price 1000 INR / Ton

Minimum Order Quantity : 27 Tons

Specific Gravity : 2.6 2.7 g/cm

Strength : High compressive and mechanical strength

Density : ~2.6 2.7 Gram per cubic centimeter(g/cm3)

Water Absorption : 1%