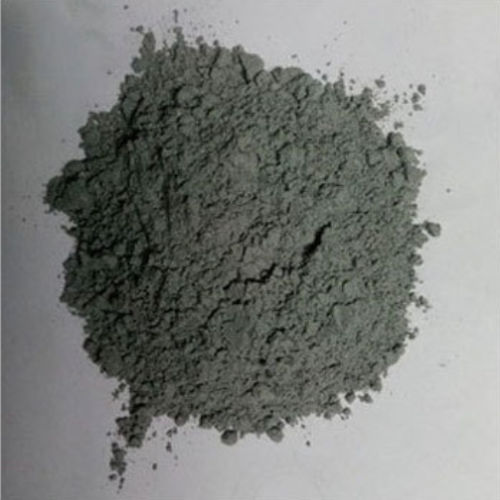

Synthetic Slag Powder

Synthetic Slag Powder Specification

- Surface Finish

- Smooth

- Density

- ~2.83.2 Gram per cubic centimeter(g/cm3)

- Water Absorption

- 25%

- Melting Point

- 13501450C

- Purity(%)

- 98%

- Usage & Applications

- Used in steelmaking as slag conditioning agent

- Types of Refractories

- Neutral Refractory

- Shape

- Powder

- Strength

- High compressive strength

- Specific Gravity

- 2.83.2 g/cm

- Color

- Gray

Synthetic Slag Powder Trade Information

- Minimum Order Quantity

- 28 Tons

- FOB Port

- JAIPUR

- Supply Ability

- 100000 Tons Per Day

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard

- Certifications

- IEC

About Synthetic Slag Powder

Synthetic slag is a synthetic aggregate, or artificial aggregate, thats made by changing the physical and chemical properties of a parent material. It has many uses, including:

Secondary steelmaking

Synthetic slag is a liquid that floats on top of liquid steel in a ladle, absorbing impurities like sulfur and non-metallic inclusions. Its basic in nature, has a high sulfide capacity, and is fluid to help reactions happen faster.

Concrete

Slag, also known as ground granulated blast furnace slag (ggbfs), can replace some of the portland cement in concrete, making it more economical and higher quality. It can also help reduce the temperature rise in large concrete sections.

Binders

Slag can be used as a binder for stabilization and solidification, along with other binders like portland cement, lime, microsilica, and magnesium oxide.

Steel refining

Synthetic slag can help refine steel, making it cleaner and desulfurizing it.

Construction materials

Ggbfs can be used as cement and concrete in construction materials.

Recycled materials

Slag is one of many industrial wastes that can be recycled into concrete, along with fly ash, silica fume, rubber tires, plastic, and stone waste.

Steel plants

Steel slag can be reused as a raw material in steel plants.

Bricks

Steel making slag can be used to make bricks that are resistant to acids and heat.

Advantages in Steelmaking

Synthetic Slag Powder enhances steel quality by refining and conditioning the slag during the smelting process. Its high purity and specific melting point make it highly effective at removing impurities, thus improving metal properties. With a smooth texture and reliable density, this powder aids in achieving optimal slag fluidity and minimizes the occurrence of inclusions, leading to cleaner finished steel products.

Trusted Distribution Across India

As a reputable manufacturer, exporter, supplier, trader, and distributor in India, we ensure timely delivery and consistent quality of our Synthetic Slag Powder. Our logistics network allows us to serve steel plants and foundries nationwide, providing tailored solutions to meet the unique needs of each facility.

FAQs of Synthetic Slag Powder:

Q: How is Synthetic Slag Powder used in steelmaking?

A: Synthetic Slag Powder is added to the molten steel bath during the steelmaking process as a slag conditioning agent. Its purpose is to refine the slag, facilitate impurity removal, and promote the formation of a homogenous slag layer to protect the metal and enhance quality.Q: What are the key benefits of this slag powder in refractory applications?

A: In neutral refractory applications, our Synthetic Slag Powder offers high compressive strength, stability at high temperatures, and effective impurity absorption. This leads to improved lining lifespan and optimal steelmaking environment.Q: Where can this product be sourced in India?

A: This product is available across India through our distribution channels. We are a leading manufacturer, exporter, supplier, and trader, ensuring easy access and prompt delivery to steelmaking units and foundries nationwide.Q: When should Synthetic Slag Powder be introduced during steel production?

A: It should be added after primary melting but before final refining processes. This timing allows the powder to absorb and neutralize impurities effectively, leading to superior slag fluidity and enhanced steel quality.Q: What is the process for applying Synthetic Slag Powder in industry?

A: The powder is typically added in controlled amounts to the molten steel, either manually or via automated dispersion systems. It then reacts with the existing slag to adjust its composition and physical properties for optimal metallurgical performance.Q: What distinguishes your Synthetic Slag Powder from other slag conditioning agents?

A: Our product features a high 98% purity, consistent particle size, smooth surface finish, and specific melting point range. These traits ensure reliable results, high reactivity, and reduced contamination during steel production.

Price 5000 INR/ Ton

- Minimum Order Quantity

- 28 Tons

- Supply Ability

- 100000 Tons Per Day

- Delivery Time

- 5 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+