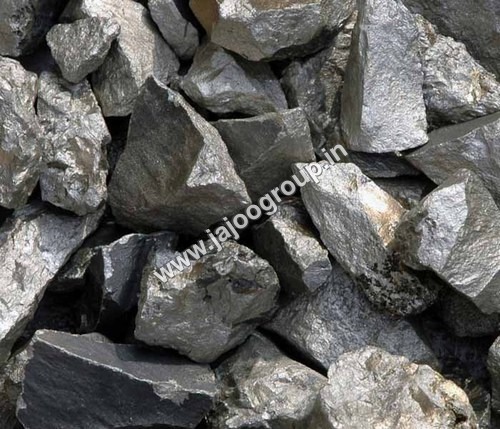

Ferro Chrome

Ferro Chrome Specification

- Product Type

- Ferroalloy

- Alloy

- Ferro Chrome

- Shape

- Lump

- Size

- Standard

- Application

- Steel Industry

- Color

- Grey

Ferro Chrome Trade Information

- Minimum Order Quantity

- 27 Tons

- Supply Ability

- 50 Tons Per Week

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- All India

About Ferro Chrome

Ferro Chrome

Our well-equipped infrastructure facility has enabled us to manufacture, supply and export Ferro Chrome. These compounds are processed in our huge infrastructure facility through the process of electric arc melting if chromite. The required compounds are obtained from the most trusted vendors of the industry. Modern techniques are used to process these compounds to offer our customers with pure Ferro Chrome. Moreover, the composition of the compounds are examined before delivery to ensure best quality compounds to our clients.

Specifications:

|

Cromium |

60-65% ( 60% pro rata basis) |

|

Carbon |

6 to 8 % |

|

Phosphorous |

0.03 % max. |

|

Silicon |

3 to 4 % |

|

Iron |

18 to 22% |

Enhancing Steel Quality with Ferro Chrome

Ferro Chrome is integral in the production of high-quality steel, giving it the necessary strength, hardness, and resistance to oxidation. Its use in various steel alloys ensures enduring performance, making it ideal for infrastructure, automotive, and engineering projects. As a versatile alloy, it ensures the end products meet stringent industry standards.

Reliable Supplier Network Across India

We serve as a trusted distributor, exporter, manufacturer, supplier, and trader of Ferro Chrome across India. Our extensive network allows us to deliver bulk quantities promptly, supporting both large-scale factories and smaller businesses. Our teams expertise guarantees consistent customer support and technical guidance during procurement and after-sales.

FAQs of Ferro Chrome:

Q: How is Ferro Chrome commonly used in the steel industry?

A: Ferro Chrome is chiefly utilized as an alloying agent in the steel industry to enhance the hardness, durability, and corrosion resistance of steel products. It is added during the steelmaking process to achieve the desired chemical composition and improve the structural quality of the end products.Q: What is the typical process of manufacturing Ferro Chrome lumps?

A: The production of Ferro Chrome lumps involves the reduction of chromite ore with carbon, usually in submerged arc furnaces. This process separates chromium from the ore, combining it with iron to form Ferro Chrome, which is then cast into standard lump shapes suitable for industrial use.Q: When should manufacturers consider using standard-sized Ferro Chrome?

A: Manufacturers should use standard-sized Ferro Chrome during key steelmaking phases where precise alloy addition is needed. Its consistent lump size allows for easier handling and accurate dosing in electric arc or induction furnaces, ensuring uniform alloying in the steel melt.Q: Where can businesses source quality Ferro Chrome in India?

A: Businesses can source high-grade Ferro Chrome from reputable distributors, exporters, manufacturers, suppliers, and traders operating across India. We are a leading supplier, offering industry-compliant products along with dependable delivery options to meet varying project requirements.Q: What are the benefits of choosing Ferro Chrome from a trusted supplier?

A: Sourcing Ferro Chrome from a trusted supplier ensures top-notch quality, consistency in chemical composition, and timely delivery. It also provides reliable technical support, tailored product solutions, and compliance with international quality standards critical for high-performance steel production.

Price 50000 INR/ Ton

- Minimum Order Quantity

- 27 Tons

- Supply Ability

- 50 Tons Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ferro Chrome Category

High Carbon Ferro Chrome

Price 50000 INR / Ton

Minimum Order Quantity : 27 Tons

Product Type : Ferroalloy

Shape : Lump

Application : Steel Industry

Color : Grey

Low Carbon Ferro Chrome

Price 50000 INR / Ton

Minimum Order Quantity : 27 Tons

Product Type : Ferroalloy

Shape : Lump

Application : Steel Industry

Color : Grey

Medium Carbon Ferro Chrome

Price 50000 INR / Ton

Minimum Order Quantity : 27 Tons

Product Type : Ferroalloy

Shape : Lump

Application : Steel Industry

Color : Grey