Quartz Powder

Quartz Powder Specification

- Density

- ~2.6 2.7 Gram per cubic centimeter(g/cm3)

- Application

- Steel, glass, and foundry industries

- Surface Finish

- Smooth

- Melting Point

- ~1710C

- Purity(%)

- 98%

- Water Absorption

- 1%

- Types of Refractories

- Basic Refractory

- Shape

- Powder

- Strength

- High compressive and mechanical strength

- Specific Gravity

- 2.6 2.7 g/cm

- Color

- White

Quartz Powder Trade Information

- Minimum Order Quantity

- 27 Tons

- FOB Port

- JAIPUR

- Supply Ability

- 50 Tons Per Week

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Exports Packaging

- Main Domestic Market

- All India

- Certifications

- ISO, MOODY RATED

About Quartz Powder

Keeping in mind the various requirements of our customers, we are able to manufacture, export and supply high-grade Quartz Powder. The offered powder is used during the manufacture of various electronic machines and appliances as these have special physical properties. The materials used to make the Quartz Powder are supplied by our trustworthy vendors of the industry. The power is processed through various machines to offer our customers with pure compounds.

Versatile Industrial Applications

Quartz Powder is a vital component in applications demanding high durability and resistance to heat, such as the steel, glass, and foundry industries. Thanks to its smooth surface finish and high purity, it delivers reliable results and enhances product performance, whether being used as a raw material or a functional additive.

Superior Material Properties

Consisting of 98% pure silica, Quartz Powder exhibits high compressive and mechanical strength, minimal water absorption, and a stable specific gravity of approximately 2.62.7 g/cm. Its smooth texture and substantial melting point (~1710C) make it suitable for basic refractory applications, enduring even the most demanding operating conditions.

FAQs of Quartz Powder:

Q: How is Quartz Powder used in the steel, glass, and foundry industries?

A: Quartz Powder is commonly incorporated as a raw material or additive to enhance durability, heat resistance, and structural integrity in steel production, glass manufacturing, and foundry operations. Its high melting point and strength make it ideal for these industrial processes.Q: What are the benefits of using high-purity Quartz Powder with a 98% silica content?

A: High-purity Quartz Powder minimizes impurities, resulting in better mechanical performance, a smoother surface finish, improved resistance to heat and corrosion, and optimal results in finished products for both foundry and glass applications.Q: When should I consider using Quartz Powder as a basic refractory material?

A: Quartz Powder is recommended for use in high-temperature environments where durability, low water absorption, and resistance to thermal shock are essential, such as in the linings of furnaces, kilns, and reactors.Q: Where can I source high-quality Quartz Powder in India?

A: You can acquire Quartz Powder from reputed distributors, exporters, manufacturers, suppliers, and traders operating throughout India, ensuring consistent quality and adherence to industrial standards.Q: What is the manufacturing process for producing Quartz Powder?

A: Quartz Powder is produced by crushing, grinding, and sieving high-quality quartz stones to achieve a uniformly fine particle size and smooth surface finish. The process preserves the materials high purity and unique properties.Q: What are the advantages of Quartz Powders high compressive and mechanical strength?

A: Its high compressive and mechanical strength ensures improved durability and structural stability in industrial applications, reducing the risk of material failure under stress or high temperatures.

Price 1000 INR/ Ton

- Minimum Order Quantity

- 27 Tons

- Supply Ability

- 50 Tons Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Quartz Powder Category

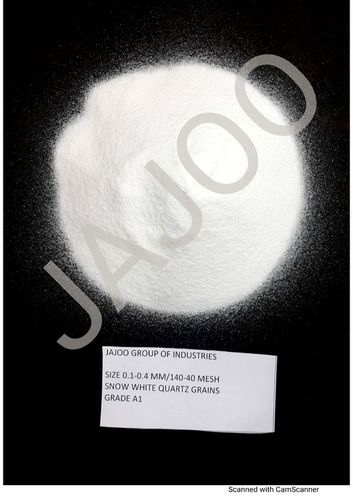

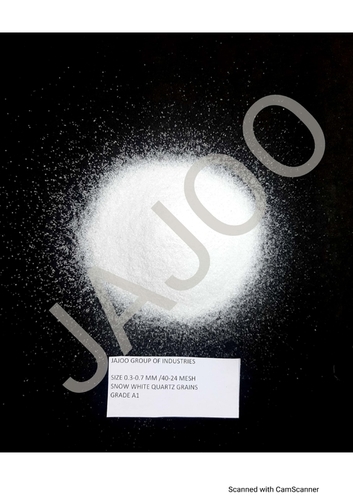

Snow White Quartz Grains

Price 2000 INR / Ton

Minimum Order Quantity : 27 Tons

Water Absorption : 1%

Types of Refractories : Other, Acidic

Shape : Powder

Strength : High compressive and mechanical strength

Quartz Grains

Price 2000 INR / Ton

Minimum Order Quantity : 27 Tons

Water Absorption : 1%

Types of Refractories : Basic Refractory

Shape : Powder

Strength : High compressive and mechanical strength

Quartz Silica Powder

Price 1000 INR / Ton

Minimum Order Quantity : 27 Tons

Water Absorption : 1%

Types of Refractories : Basic Refractory

Shape : Powder

Strength : High compressive and mechanical strength