Quartz Silica Powder

Quartz Silica Powder Specification

- Density

- ~2.6 2.7 Gram per cubic centimeter(g/cm3)

- Surface Finish

- Smooth

- Water Absorption

- 1%

- Melting Point

- ~1710C

- Application

- Steel, glass, and foundry industries

- Product Type

- Mineral Refractories

- Types of Refractories

- Basic Refractory

- Shape

- Powder

- Strength

- High compressive and mechanical strength

- Specific Gravity

- 2.6 2.7 g/cm

- Color

- White

Quartz Silica Powder Trade Information

- Minimum Order Quantity

- 27 Tons

- FOB Port

- JAIPUR

- Supply Ability

- 50 Tons Per Week

- Delivery Time

- 1 Week

- Packaging Details

- Exports Packaging

- Main Domestic Market

- All India

- Certifications

- ISO, Moody Rated

About Quartz Silica Powder

The most prevalent and plentiful mineral on Earth is quartz. It is present in practically all geological settings and makes up at least a portion of almost all rock types. It is formed of trigonal crystalline silica and has a hexagonal crystal structure. In terms of variety, colours, and forms, it is the most diversified.

The most significant difference between the two varieties of quartz is that one is macrocrystalline, meaning that individual crystals are visible to the naked eye, and the other is microcrystalline, also known as cryptodrystalline varieties, meaning that aggregates of crystals are only visible when viewed under a powerful microscope. The general name for cryptocrystalline quartz is chalcedony. The cryptocrystalline types are either translucent or primarily opaque, with the transparent form typically being macrocrystalline.

Exceptional Mechanical Performance

Quartz Silica Powder is valued for its outstanding compressive and mechanical strength, which ensures durability even in extreme industrial environments. Its high melting point and stability make it essential for the steel and glass sectors. With minimal water absorption and a refined, smooth surface finish, it provides consistent performance, supporting efficient production processes in various industries.

Versatile Applications in Industries

This powder finds critical application in steel-making, glass production, and foundry work. Its basic refractory properties allow it to withstand high temperatures and aggressive chemical environments. Manufacturers, exporters, and distributors across India rely on Quartz Silica Powder for its reliability, purity, and tailored properties, making it a key material for industrial processes requiring high strength and stability.

FAQs of Quartz Silica Powder:

Q: How is Quartz Silica Powder typically used in the steel and glass industries?

A: Quartz Silica Powder is used as a refractory material in the steel and glass industries due to its high melting point and durability. In steel manufacturing, it helps line furnaces and ladles, while in glass production it serves as a raw material for making high-quality transparent glass.Q: What are the benefits of using Quartz Silica Powder in foundry applications?

A: The powders high mechanical and compressive strength make it ideal for forming strong molds and cores in foundry applications. Its smooth surface finish and low water absorption ensure precise casting and minimal defects, improving overall product quality.Q: Where can I source Quartz Silica Powder in India?

A: Quartz Silica Powder is readily available across India from a range of suppliers, including manufacturers, exporters, distributors, and traders. These suppliers typically ensure quality control and can provide bulk quantities to suit different industrial needs.Q: What is the production process for Quartz Silica Powder?

A: Quartz Silica Powder is produced by mining high-purity quartz, followed by crushing, grinding, and precise classification into a fine powder. Additional steps may include washing and surface treatment to achieve the required smoothness and chemical stability.Q: When should I choose Quartz Silica Powder as a refractory material?

A: Quartz Silica Powder should be chosen when high-temperature resistance and mechanical strength are required, especially in steel, glass, and foundry industries. Its refractory properties make it suitable for lining furnaces, manufacturing molds, and supporting high-stress applications.Q: What are the handling and storage requirements for this powder?

A: Quartz Silica Powder should be stored in a dry location to avoid moisture absorption, which can affect its performance. Use proper dust collection and protective equipment during handling to minimize inhalation exposure and maintain workplace safety.

Price 1000 INR/ Ton

- Minimum Order Quantity

- 27 Tons

- Supply Ability

- 50 Tons Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Quartz Powder Category

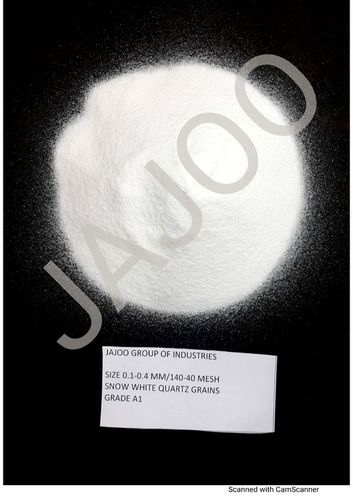

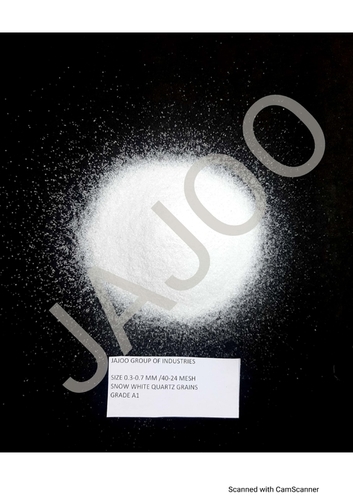

Snow White Quartz Grains

Price 2000 INR / Ton

Minimum Order Quantity : 30 Tons

Purity(%) : 99%

Strength : High compressive and mechanical strength

Color : White

Types of Refractories : Other, Acidic

Quartz Powder

Price 1000 INR / Ton

Minimum Order Quantity : 27 Tons

Purity(%) : 98%

Strength : High compressive and mechanical strength

Color : White

Types of Refractories : Basic Refractory

Quartz Grains

Price 2000 INR / Ton

Minimum Order Quantity : 27 Tons

Purity(%) : 98%

Strength : High compressive and mechanical strength

Color : White

Types of Refractories : Basic Refractory